Brand Name: Baode

Model Number: BB60/BH60 series

Place of Origin: China

|

Model |

BH60 |

|

|

Cross Reference ALFA LAVAL |

M6, M6M |

|

|

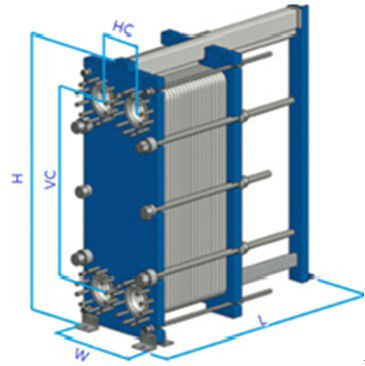

Height, H [mm] |

920 |

940 |

|

Width, W [mm] |

320 |

330 |

|

Min standard length, L [mm] |

500 |

500 |

|

Max standard length, L [mm] |

1500 |

1500 |

|

Vertical port distance, VC [mm] |

640 |

640 |

|

Horizontal port distance, HC [mm] |

140 |

140 |

|

Max temperature [°C] |

180 |

180 |

|

Max pressure [barg] |

10 |

16 |

|

Flange size |

DN50/2” |

DN50/2” |

|

Max. flow rate [kg/s] |

16 |

|

(Measurment in mm, N means the number of the plates)

|

Material of Plate |

Suited Liquid Kinds |

||

|

Stainless Steel (AISI304.316 Etc) |

Pure Water, Normal Water, Oil for eating, Mineral Oil |

||

|

Ti, Ti-pd |

Sea Water, Saline Water, Mineral Water |

||

|

20Cr, 18Ni, 6Mo (254SMO) |

Dilute Sulphuric Acid, Organic Water Solution |

||

|

Ni |

High-temp and concentration caustic soda |

||

|

Hastelloy (C276, D205, B2G) |

Concentration Sulphuric Acid, Hydrochloric acid, Phosphoric acid |

||

|

Material of Gasket |

Operating Temperature ° C |

Suited Liquid Kinds |

|

|

NBR |

-15~+135° C |

Water, Sea Water, Mineral Oil, Salinous Water |

|

|

EPDM |

-25~+180° C |

Hot Water, Steam, Acid, Alkali |

|

|

F26 |

-55~+230° C |

Acid, Alkali |

|

|

TPF |

0~+160° C |

High Concentrated Acid, Alkali, High temperature Oil, Steam |

|

Application

Swimming pool water heating. Simple, strong, compact and

highly reliable, the Baode Gasket Plate heat exchanger BH60B is designed to efficiently reheat

and maintain temperature of water in swimming pools of all

dimensions and capacities from primary heat source such as

boiler, solar installation, heat pump etc.

Standard design

Complete packaged module including:

Stainless steel or titanium plate heat exchanger, for operation with sea water or slightly corrosive water (balneo-therapy,

thermal spring water), NBR or EPDM clip-on gaskets.

Typical capacities

Liquid flow rate

Up to 16 kg/s (250 gpm), depending on media, permitted

Pressure drop and temperature program.

Water heating by steam

300 to 800 kW

Working principle

Channels are formed between the plates and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, and complete counter-current flow is created for highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer.

Short delivery time.

High quality

Reasonable price

Customer made

Know-how design and customer support

Certified by ISO9001, CE, UL, WRAS, ROHS, CCS etc.